Vertical Mobile Dry Fog Hydrogen Peroxide Sterilizer

![]()

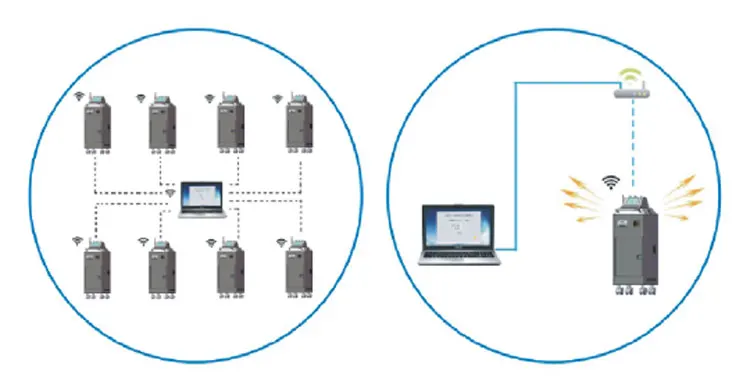

IFog 2000 mobile hydrogen peroxide sterilization system is based on the principle of cold evaporation gasification (DFS) technology, which can be developed to sterilize more space, and can be controlled by multiple computers. IFog 2000 hydrogen peroxide sterilization system can be multi-point on-line control, up to 8 on-line, to achieve 3000 cubic complex space sterilization. Online control scheme can synchronously open all sterilizers, adopt a control system, synchronously control all equipment start and stop, synchronously record all equipment data. Key advantages: short sterilization period and good effect. Key point: There will be no corrosion to the color steel plate!

![]()

| Spray particle size | 1-3 M |

| Working power supply | AC220V + 10% 50Hz |

| Spray speed | 18m/ seconds. |

| Maximum spray volume | 30ml/min |

| Complex sporicide capacity | <2000ml |

| Applicable sporicide | MicroKill space sporicide |

| Killing rate | 6-log decrease for Bacillus stearophilus |

| Power | <2000W |

| Sterilization volume | <500 cubic meters |

| Material | Stainless steel |

| Size | 300 cm *355 cm *1000 cm (L*W*H) (single point) |

![]()

1. The device control has the function of double screen selection. It can be controlled either by self-contained LCD screen or by remote computer.

2. It has the function of U-disk data export, and can export and store the corresponding sterilization records. 3. Optional distribution of multi-point sterilization scheme, multi-sterilizers can work together, so that sterilization in a wide range of space without dead angle.

4. Multi-point temperature and humidity sensor can be selected for remote computer control to verify and record the sterilization effect.

5. It can store 8 kinds of sterilization process templates. Different rooms can call the corresponding template settings without re-entering the settings every time they are used.

6. Built-in weighing module with minimum precision of 1G can accurately control the total spraying quantity of sterilization process, and avoid the phenomenon that excessive spraying and insufficient spraying result in unsatisfactory sterilization effect.

7. The built-in dosing quantitative fixed speed timing device can ensure the uniformity of spraying quantity.

8. It has the function of time reservation and can set working hours by itself.

9. It has printing function. When sterilizing, it can print the information of current working state and temperature and humidity in real time for inquiring the working state after sterilization.

10. Sterilizer has wireless communication function. It can communicate with remote monitoring terminal through terminal wireless adapter. Sterilization status and temperature and humidity information can be monitored remotely and real-time, and the working status of the sterilizer can be controlled remotely.

11. Selecting and matching the detection module of hydrogen peroxide killing efficiency can monitor the distribution of hydrogen peroxide concentration in the working environment in real time.

12. The equipment has three levels of password management authority, audit and tracking function to ensure data integrity. Key advantages: color steel plate will not be corroded.

![]()